About Rantec

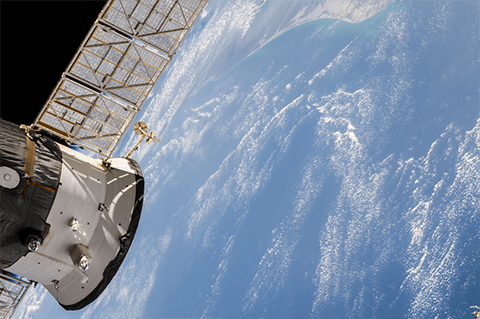

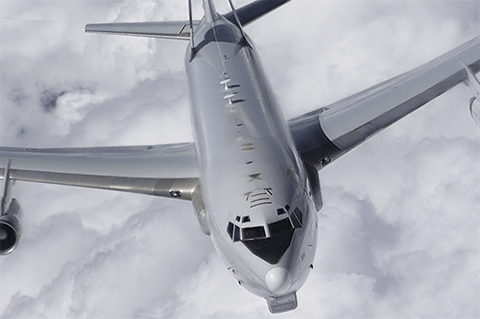

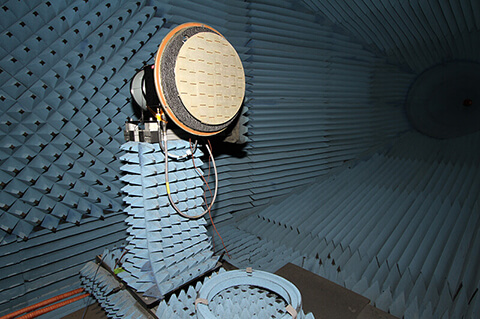

A leader in the antenna industry for over 60 years, the Rantec Microwave Systems name has been synonymous with innovative design, high quality and high reliability. Rantec antennas are in use throughout the world for both military and commercial applications such as radar, missile guidance, navigation, satellite communications and space. Our personnel have the experience, skills and equipment necessary to design and manufacture products that can meet even the most stringent environmental requirements.

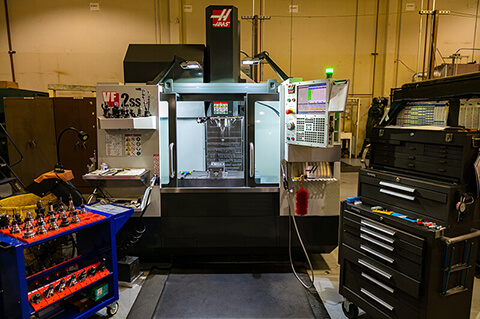

Rantec offers our unique combined capability of in-house precision machining and dip braze for aluminum as a subcontract service.

In most cases, because we have all the facilities to deliver machined and dip brazed parts under one roof, we save customers not only money but time.

Dip Braze

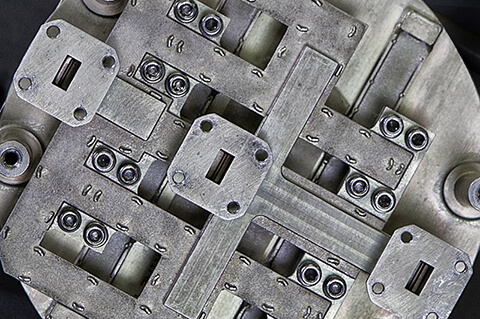

About Dip Braze

The dip brazing process allows simultaneous joining of aluminum components with varying material thickness. Dip brazed joints are very strong, leak-tight and electrically conductive.

Rantec is exceptionally adept and proficient with the salt bath dip brazing method for the process of joining precise aluminum alloy components. We take pride in maintaining the tight process controls necessary to ensure that intricate and delicate microwave antenna assemblies requiring dip brazing are manufactured to specification.

The requirements of AWS C3.7, Grade C (previously MILB-7883, Type V, Grade B) are met at Rantec and quality programs are maintained to ensure consistent and reliable service performance.