We are committed to providing world class Microwave communications products that exceed the quality standards and expectations of our customers, while maintaining a quality system directed towards continuous, measurable improvement.

Rantec is certified to AS9100D and is registered through BSI Management Systems America, Inc.

Rantec’s Quality Program is a documented, systematic plan created to support and meets the requirements in the manufacture of microwave antennas for Military and Commercial applications.

Our Quality Program ensures that Rantec processes and products are controlled through all stages of development, design, production and preparation for delivery and will meet the highest quality and reliability standards as required by Rantec and its customers.

Quality procedures and instructions are controlled and accessible to all Rantec personnel through our internal computer database. Rantec inspection personnel have access to a computer and document inspection results assisting in the monitoring of work in process status and appraising manufacturing and vendor quality.

Acceptance Quality levels for Receiving Inspection, In-Process inspection and Final inspection are monitored along with on time delivery of product to our Customers. Results are charted and monthly reports generated and posted for review by manufacturing supervisors, managers and Top Management.

- Contract Review QOP - 100

- Calibration System QOP - 201 Per ANSI/NCSL Z540-1

- Drawing and Change Control QOP - 203

- Prevention of Counterfeit Part and Obsolescence Monitoring QOP - 208

- Procurement Control QOP - 300

- Receiving Inspection QOP - 303

- Foreign Object Damage / Debris (FOD) Prevention QOP - 307

- Acceptance Testing QOP - 403

- Nonconforming Material Control QOP - 405

- Internal Corrective Action QOP- 406

- Internal Quality Audits QOP - 407

- Control of Government / Customer Furnished Property QOP - 408

- Inspection (In-process, Final) QCI - 402.2 & 402.6

- Final Shipping Inspection QCI - 404.1

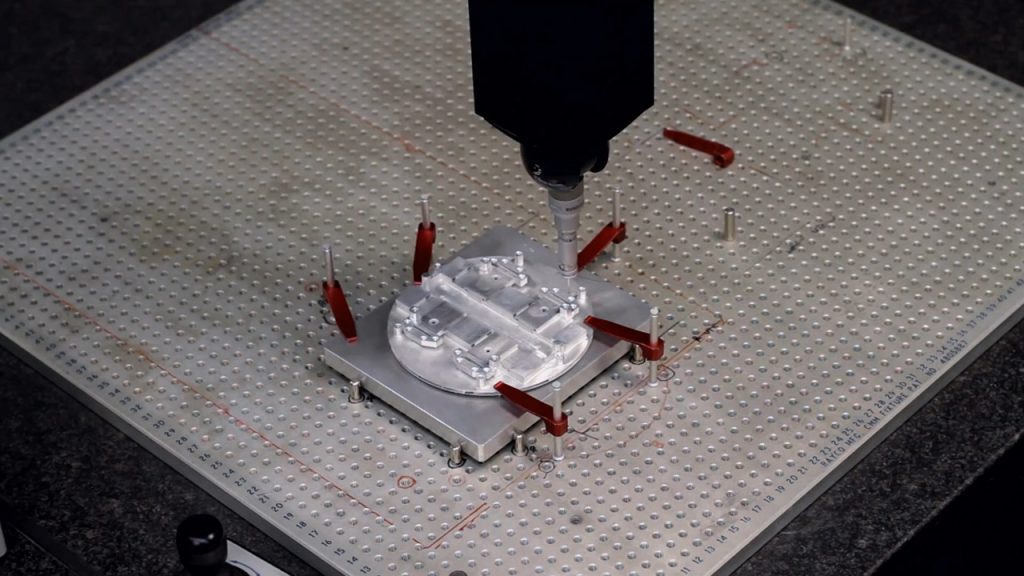

Rantec Inspection department equipment for verification of product include:

- (2) Automated Computer-assisted, programmable Coordinated Measure System, using PC-DIM CAD ++ (DCC) for Windows 2000 software.

- (1) Starrett Computer-assisted and Coordinated Measure Machine

- (1) Optical Comparators with digital readout

- X-Ray equipment for diagnostic evaluations

- Rockwell hardness verification